Join the club

Get exclusive deals and early access to new products.

POLOLU

This gearmotor consists of a high-power, 6 V brushed DC motor combined with a 20.4:1 metal spur gearbox, and it has an integrated 48 CPR quadrature encoder on the motor shaft, which provides 979.62 counts per revolution of the gearbox’s output shaft. The gearmotor is cylindrical, with a diameter just under 25 mm, and the D-shaped output shaft is 4 mm in diameter and extends 12.5 mm from the face plate of the gearbox.

Key specs at 6 V: 460 RPM and 550 mA free-run, 75 oz-in (5.5 kg-cm) and 6.5 A stall.

You can use the following selection boxes to choose from all of our 25D metal gearmotor versions:

These cylindrical brushed DC gearmotors are available in a wide range of gear ratios and with five different motors (two power levels of 6V motors and three power levels of 12V motors). The gearmotors all have the same 25 mm diameter case and 4 mm diameter gearbox output shaft, so it is generally easy to swap one version for another if your design requirements change (though the length of the gearbox tends to increase with the gear ratio). All versions are also available with an integrated 48 CPR quadrature encoder on the motor shaft.

Details for item #2272

Exact gear ratio: 22×22×22×2312×10×10×10≈20.4:122×22×22×2312×10×10×10≈20.4:1

Dimensions

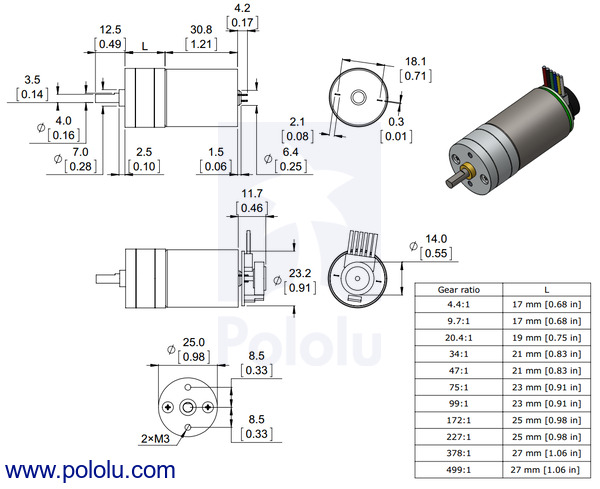

The diagram below shows the dimensions of the 25D mm line of gearmotors (units are mm over [inches]).

|

|

Dimensions of the Pololu 25D mm metal gearmotors. Units are mm over [inches]. |

|---|

Using the encoder (if applicable)

The versions of these gearmotors with encoders use a A two-channel Hall effect sensor to detect the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 48 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 48. The motor/encoder has six color-coded, 8″ (20 cm) leads terminated by a 1×6 female header with a 0.1″ pitch, as shown in the main product picture. This header works with standard 0.1″ male headers and our male jumperand precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Color | Function |

|---|---|

| Red | motor power (connects to one motor terminal) |

| Black | motor power (connects to the other motor terminal) |

| Green | encoder GND |

| Blue | encoder Vcc (3.5 – 20 V) |

| Yellow | encoder A output |

| White | encoder B output |

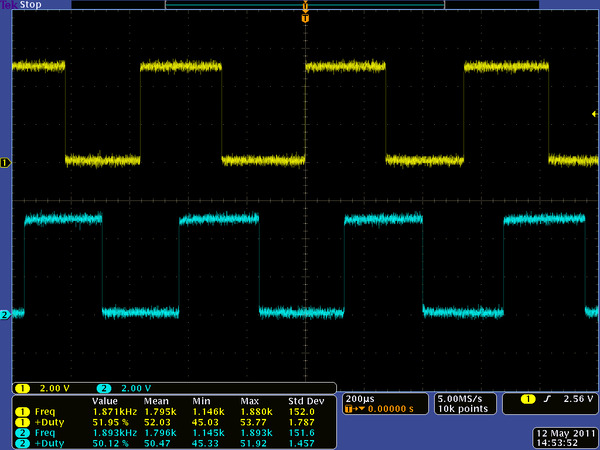

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a motor voltage of 6 V and a Hall sensor Vcc of 5 V:

|

|

Encoder A and B outputs for 25D mm HP 6V metal gearmotor with 48 CPR encoder (motor running at 6 V). |

|---|

By counting both the rising and falling edges of both the A and B outputs, it is possible to get 48 counts per revolution of the motor shaft. Using just a single edge of one channel results in 12 counts per revolution of the motor shaft, so the frequency of the A output in the above oscilloscope capture is 12 times the motor rotation frequency.