Join the club

Get exclusive deals and early access to new products.

POLOLU

The Pololu AltIMU-10 is an inertial measurement unit (IMU) and altimeter that features the same L3GD20 gyro and LSM303DLHC accelerometer and magnetometer as the MinIMU-9 v2, and adds an LPS331AP digital barometer. An I²C interface accesses ten independent pressure, rotation, acceleration, and magnetic measurements that can be used to calculate the sensor’s altitude and absolute orientation. The board operates from 2.5 to 5.5 V and has a 0.1″ pin spacing.

The Pololu AltIMU-10 is a compact (1.0″ × 0.5″) board that combines ST’s LPS331AP digital barometer, L3GD20 3-axis gyroscope, and LSM303DLHC 3-axis accelerometer and 3-axis magnetometer to form an inertial measurement unit (IMU) and altimeter; we therefore recommend careful reading of the LPS331AP datasheet (453k pdf), L3GD20 datasheet (2MB pdf), and LSM303DLHC datasheet (629k pdf) before using this product. These sensors are great ICs, but their small packages make them difficult for the typical student or hobbyist to use. They also operate at voltages below 3.6 V, which can make interfacing difficult for microcontrollers operating at 5 V. The AltIMU-10 addresses these issues by incorporating additional electronics, including a voltage regulator and a level-shifting circuit, while keeping the overall size as compact as possible. The board ships fully populated with its SMD components, including the L3GD20, LSM303, and LPS331, as shown in the product picture.

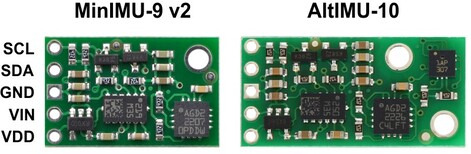

The AltIMU-10 is pin-compatible with the MinIMU-9 v2 and offers the same functionality augmented by a digital barometer that can be used to obtain pressure and altitude measurements. It includes a second mounting hole and is only 0.2″ longer than the MinIMU-9 v2. Any code written for the MinIMU-9 v2 should also work with the AltIMU-10.

|

| Side-by-side comparison of the MinIMU-9 v2 with the AltIMU-10. |

|---|

The LPS331AP, L3GD20, and LSM303DLHC have many configurable options, including selectable resolutions for the barometer and dynamically selectable sensitivities for the gyro, accelerometer, and magnetometer. Each sensor also has a choice of output data rates. The three ICs can be accessed through a shared I²C/TWI interface, allowing all four sensors to be addressed individually via a single clock line and a single data line.

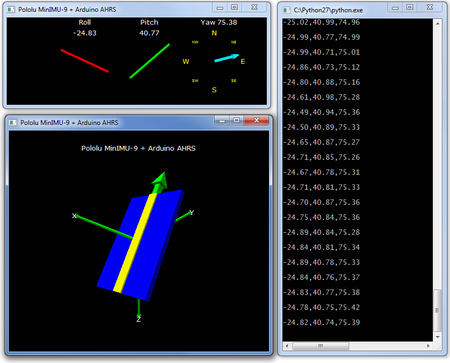

The nine independent rotation, acceleration, and magnetic readings provide all the data needed to make an attitude and heading reference system (AHRS), and readings from the absolute pressure sensor can be easily converted to altitudes, giving you a total of ten independent measurements (sometimes called 10DOF). With an appropriate algorithm, a microcontroller or computer can use the data to calculate the orientation and height of the AltIMU board. The gyro can be used to very accurately track rotation on a short timescale, while the accelerometer and compass can help compensate for gyro drift over time by providing an absolute frame of reference. The respective axes of the two chips are aligned on the board to facilitate these sensor fusion calculations. (For an example of such a system using an Arduino, see the picture below and the Sample Code section at the bottom of this page.)

|

| Visualization of AHRS orientation calculated from MinIMU-9 readings. |

|---|

The carrier board includes a low-dropout linear voltage regulator that provides the 3.3 V required by the LPS331, L3GD20, and LSM303, allowing the module to be powered from a single 2.5 V to 5.5 V supply. The regulator output is available on the VDD pin and can supply almost 150 mA to external devices. The breakout board also includes a circuit that shifts the I²C clock and data lines to the same logic voltage level as the supplied VIN, making it simple to interface the board with 5 V systems. The board’s 0.1″ pin spacing makes it easy to use with standard solderless breadboards and 0.1″ perfboards.

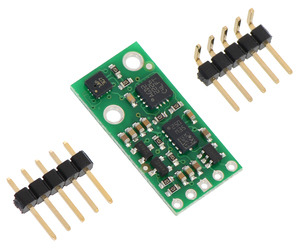

A 1×5 strip of 0.1″ header pins and a 1×5 strip of 0.1″ right-angle header pins are included, as shown in the picture below. You can solder the header strip of your choice to the board for use with custom cables or solderless breadboards or solder wires directly to the board itself for more compact installations. The board features two mounting holes that work with #2 or M2screws (not included).

|

A minimum of four connections are necessary to use the AltIMU-10: VIN, GND, SCL, and SDA. VIN should be connected to a 2.5 V to 5.5 V source, GND to 0 volts, and SCL and SDA should be connected to an I²C bus operating at the same logic level as VIN. (Alternatively, if you are using the board with a 3.3 V system, you can leave VIN disconnected and bypass the built-in regulator by connecting 3.3 V directly to VDD.)

|

|

| PIN | Description |

|---|---|

| SCL | Level-shifted I²C clock line: HIGH is VIN, LOW is 0 V |

| SDA | Level-shifted I²C data line: HIGH is VIN, LOW is 0 V |

| GND | The ground (0 V) connection for your power supply. Your I²C control source must also share a common ground with this board. |

| VIN | This is the main 2.5 V to 5.5 V power supply connection. The SCL and SDA level shifters pull the I²C bus high bits up to this level. |

| VDD | 3.3 V regulator output or low-voltage logic power supply, depending on VIN. When VIN is supplied and greater than 3.3 V, VDD is a regulated 3.3 V output that can supply up to approximately 150 mA to external components. Alternatively, when interfacing with a 2.5 V to 3.3 V system, VIN can be left disconnected and power can be supplied directly to VDD. Never supply voltage to VDD when VIN is connected, and never supply more than 3.6 V to VDD. |

The data ready and interrupt pins of the LPS331AP, L3GD20, and LSM303DLHC are not accessible on the AltIMU-10; if you need these outputs, consider using ourLPS331AP carrier, L3GD20 carrier, and LSM303DLHC carrier boards.

|

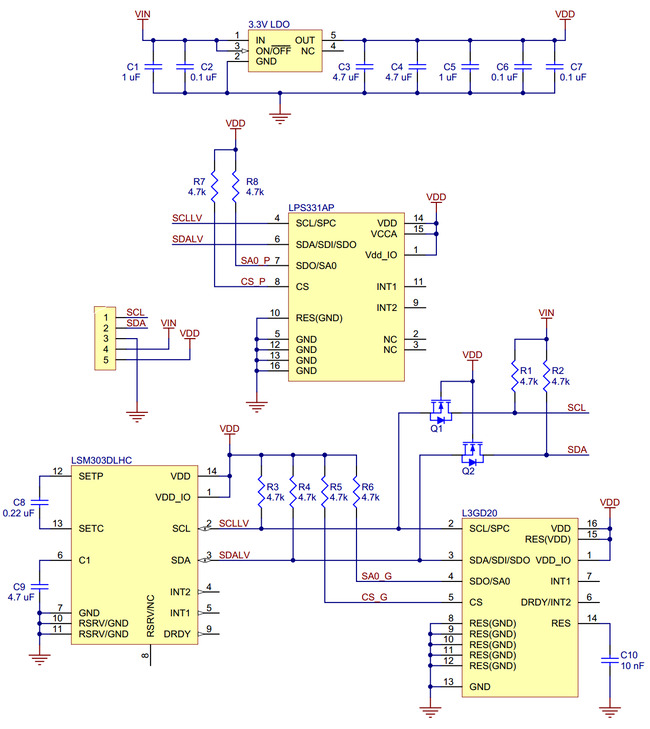

The above schematic shows the additional components the carrier board incorporates to make the LPS331AP, L3GD20, and LSM303DLHC easier to use, including the voltage regulator that allows the board to be powered from a single 2.5 V to 5.5 V supply and the level-shifter circuit that allows for I²C communication at the same logic voltage level as VIN. This schematic is also available as a downloadable pdf: AltIMU-10 schematic (193k pdf).

The LPS331AP’s barometer, the L3GD20’s gyro, and the LSM303DLHC’s accelerometer and magnetometer can be queried and configured through the I²C bus. Each of the four sensors acts as a slave device on the same I²C bus (i.e. their clock and data lines are tied together to ease communication). Additionally, level shifters on the I²C clock (SCL) and data lines (SDA) enable I²C communication with microcontrollers operating at the same voltage as VIN (2.5 V to 5.5 V). A detailed explanation of the protocols used by each device can be found in theLPS331AP datasheet (453k pdf), the L3GD20 datasheet (2MB pdf), and the LSM303DLHC datasheet (629k pdf). More detailed information about I²C in general can be found in NXP’s I²C-bus specification (371k pdf).

The barometer, gyro, accelerometer, and magnetometer each have separate slave addresses on the I²C bus. The board pulls the SA0 pins on the gyro and barometer high. The following table shows the slave addresses of the four sensors:

| Sensor | Slave Address |

|---|---|

| Gyro (L3GD20) | 1101011b |

| Accelerometer (LSM303DLHC) | 0011001b |

| Magnetometer (LSM303DLHC) | 0011110b |

| Barometer (LPS331AP) | 1011101b |

In our tests of the AltIMU-10, we were able to communicate with all three chips at clock frequencies up to 400 kHz; higher frequencies might work but were not tested. The chips themselves and carrier board do not meet some of the requirements to make the devices compliant with I²C fast mode. They are missing 50 ns spike suppression on the clock and data lines, and additional pull-ups on the clock and data lines might also be necessary to achieve compliant signal timing characteristics.

Sample Code

We have written a basic LPS331 Arduino library, L3GD20 Arduino library, and LSM303 Arduino library that make it easy to interface the AltIMU-10 with an Arduino. They also make it simple to configure the sensors and read the raw pressure, gyro, accelerometer, and magnetometer data.

For a demonstration of what you can do with this data, you can turn an Arduino connected to a AltIMU-10 into an attitude and heading reference system, or AHRS, with this Arduino program. It uses the data from the AltIMU-10 to calculate estimated roll, pitch, and yaw angles, and you can visualize the output of the AHRS with a 3D test program on your PC (as shown in a screenshot above). This software is based on the work of Jordi Munoz, William Premerlani, Jose Julio, and Doug Weibel.

Protocol Hints

The datasheets provide all the information you need to use the sensors on the AltIMU-10, but picking out the important details can take some time. Here are some pointers for communicating with and configuring the LPS331AP, L3GD20, and LSM303DLHC that we hope will get you up and running a little bit faster: